Triisobutyl phosphate TIBP (CAS 126-71-6) is clorless transparent liquid, used for textile auxiliaries, penetrating agent, dye auxiliaries, etc.Triisobutyl Phosphate(TIBP) is mainly used for antifoamer and penetrant. It is also be widely used in printing and dying, ink, construction, and oil field additives, etc.

Specification

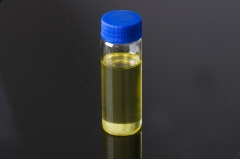

Appearance Colorless transparent liquid

Purity ≥ 99%

Refractive index nD20 1.4190-1.4200

Density (20)g/ml 0.960-0.970

H2O ≤0.1%

Acid value mg KOH/g ≤0.1%

Application

Triisobutyl phosphate TIBP is a very strong solvent used for liquefying concrete, textile auxiliaries, paper coating compounds etc.

Triisobutyl phosphate TIBP is a strong polar solvent, mainly used as an antifoaming agent in various aqueous systems where it has the ability to both destroy foam and act as a foam inhibitor.

Triisobutyl phosphate TIBP is also used in the reduction of solutions of synthetic resins and natural rubber. In both ellulose-based plastics and synthetic resins, it is used as a flame-retarding plasticizer.

Triisobutyl phosphate TIBP is also used as a paste agent for pigment pastes. Due to the limited influence of temperature on the viscosityof TiBP, it also serves as an important component in the manufacture of hydraulic fluids for aircrafts. as a very strong wetting aent, TiBP is used in the textile industry and in the fields of adhesives.

Triisobutyl phosphate TIBP is mainly used for textile auxiliaries, penetrating agent, dye auxiliaries, etc。

Triisobutyl phosphate TIBP is widely used in dyeing, printing ink, construction, oil additives and other industries and fields.

Packaging

200kg/drum, 16mt/20’’container

1000kg/IBC drum, 20mt/20”containerStorage & Handling

If stored correctly and kept in the original sealed container, the product has a shelf life of at least 24 months.

Metallic materials such as stainless steel and aluminum, as well as ceramic apparatus components have proved suitable. Materials suitable for seals are polyethylene, poly tetrafluoro ethylene (PTFE) and graphite.Strong swelling may occur when plastic (PVC in particular) and rubber components are used as well as upon contact with the interior coatings of vessels. Testing of the resistance is therefore recommended.

Always refer to the Material Safety Data Sheet (MSDS) for detailed information on handling and disposal.

chemical.tnj

chemical.tnj +8618949823763

+8618949823763 tnjchem

tnjchem 2881500864

2881500864